Oxygen, as a rich gas in the air, is inexhaustible and used inexhaustible. It is colorless, odorless, transparent and life-sustaining. The content of oxygen (O2) in the air is 20.9476%(the volume group of various gases in the air is divided into: N2:78.084%, O2:20.9476%, argon: 0.9364%, CO2: 0.0314%, other H2, CH4, O3, SO2, NO2, etc., but the content is very small), molecular weight is 32, boiling point: -183℃.

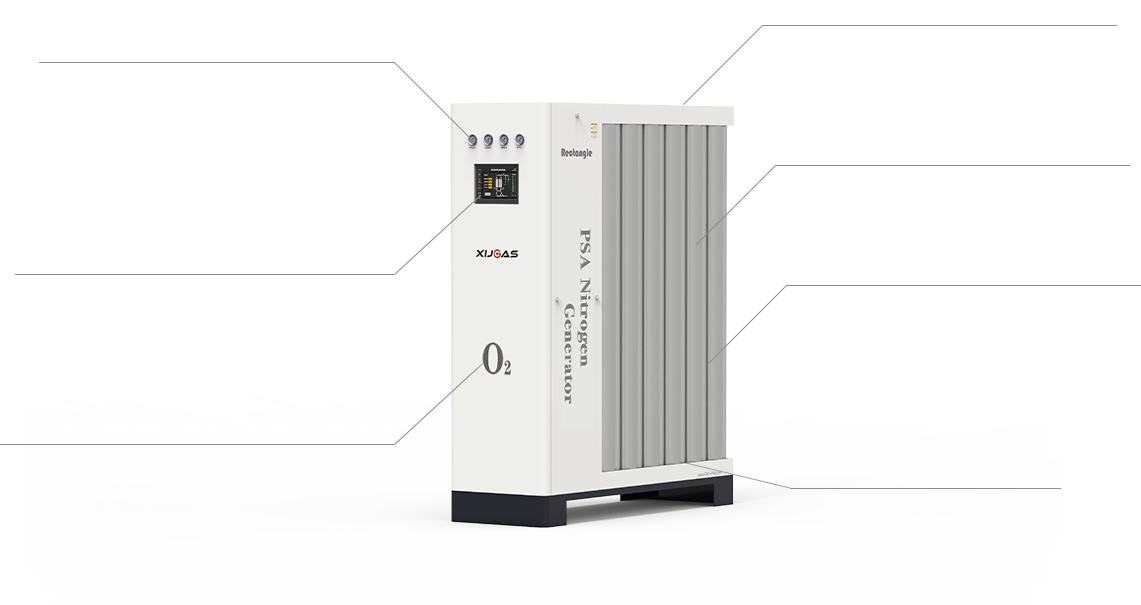

Modular oxygen generator with clean and dry compressed air as raw material, the selection of zeolite molecular sieve as adsorbent, through a specific process to complete the separation of oxygen and nitrogen, stable and continuous supply of high purity oxygen. More economical, more reliable, more efficient and more secure than traditional methods.

● The RE series oxygen generator (modular oxygen generator) is composed of two die-cast aluminum cylinders arranged in pairs, filled with zeolite molecular sieve through vacuum suction, and connected into a whole through the upper and lower gas chambers to form a mutual switching adsorption separation system.

● An automated device that uses the principle of pressurized adsorption and depressurized desorption to adsorb and release nitrogen from the air, thereby separating oxygen.

● Zeolite molecular sieve is a kind of special pass processing process, the surface and interior of the microporous spherical particle adsorbent is white. Its pass characteristics enable it to achieve kinetic separation of O2 and N2.

● The separation effect of zeolite molecular sieve on O2 and N2 is based on the slight difference in kinetic diameters of the two gases. N2 molecules have a faster diffusion rate in the micropores of zeolite molecular sieve, while O2 molecules have a slower diffusion rate.

● The diffusion of water and CO2 in compressed air is not very different from that of nitrogen. What eventually comes out of the adsorption tower is oxygen molecules.

Safe And Reliable Compared with traditional bottled gas and liquid nitrogen, the production process is safer, the use of more worry, all the gas is in control, not affected by the transportation cycle and price |

Low Noise On-site nitrogen production, unique muffler and auxiliary filling muffler structure for more peace of mind |

Easy To Install Small footprint, flexible and convenient |

Conform To Specifications High quality and high purity nitrogen, equipment design meets GB/T 150.1-2011 standard, nitrogen quality meets food grade E941 standard |

Performance Guarantee Stable PSA technology, 100% functional and parameter testing before delivery 1 year warranty, 24×7 hours timely response |

Economic Sustainability Short return on investment, nitrogen output on demand, saving operating costs |

扫码关注