When large amounts of nitrogen are needed to assist production operations, the traditional way of the industry is non-standard customization.

When large amounts of nitrogen are needed to assist production operations, the traditional way of the industry is non-standard customization.

Resulting in the final delivery of the product appearance of large volume, does not meet the needs of the site, transportation and installation security risks, uneven product structure, is not conducive to standardized management, product quality is uncontrollable, increase the cost of maintenance and use.

Resulting in the final delivery of the product appearance of large volume, does not meet the needs of the site, transportation and installation security risks, uneven product structure, is not conducive to standardized management, product quality is uncontrollable, increase the cost of maintenance and use.

● The Extension series still adopts PSA (pressure swing adsorption) technology, takes zeolite sieve as adsorbent, and uses the principle of pressure adsorption and step-down desorption to adsorb oxygen from the air, so as to separate nitrogen from the automatic equipment. Zeolite molecular sieve is a kind of special pass processing process, the surface and interior of the microporous spherical particle adsorbent is white.

● Its pass characteristics enable it to achieve kinetic separation of O2 and N2.

● The separation effect of zeolite molecular sieve on O2 and N2 is based on the slight difference in the kinetic diameter of the two gases. N2 molecules have a faster diffusion rate in the micropores of zeolite molecular sieve, while O2 molecules have a slower diffusion rate. The diffusion of water and CO2 in compressed air is not much different from that of nitrogen, and oxygen molecules are finally enriched from the adsorption tower.

Elastic Design The patented combined module and noise reduction filter shunt device can realize various appearance gas |

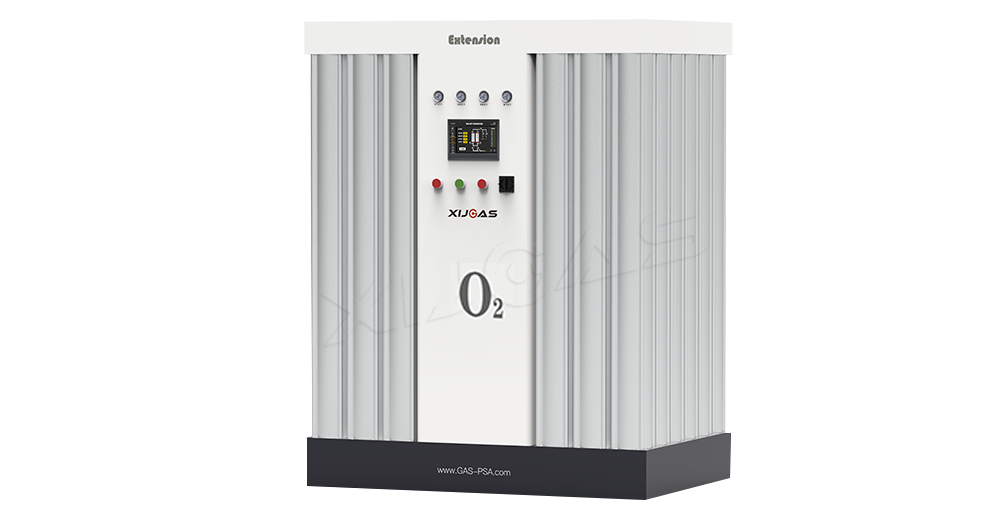

Safe And Convenient Compared with the traditional industry, does not contain pressure vessels, elegant appearance, compact structure standards, small footprint, adsorption module design in line with national norms, safe, convenient and no hidden dangers. |

Energy-Saving aAd Efficient Standard adsorption module design, unique gas diverting device, nitrogen production high efficiency and high purity, compared with the traditional equipment more energy saving |

Customized demand To meet special motion use scenarios, module units can be used with containers, mobile operations, etc |

Industrial Intelligence The equipment is equipped with an operable touch screen and a stable PLC to display parameters such as adsorption and blowdown process, valve action, nitrogen purity, real-time flow rate, running time, and service prompt in real time. At the same time, there is a secondary login password to prevent non-professionals from changing the operating data |

Life guarantee The electrical components and control valves are imported with industry-verified high quality brands to ensure control accuracy and service life. The anti-corrosion design of the adsorption module is adopted, and the anodic oxidation sandblasting process is adopted to prevent the corrosion of traditional equipment |

扫码关注